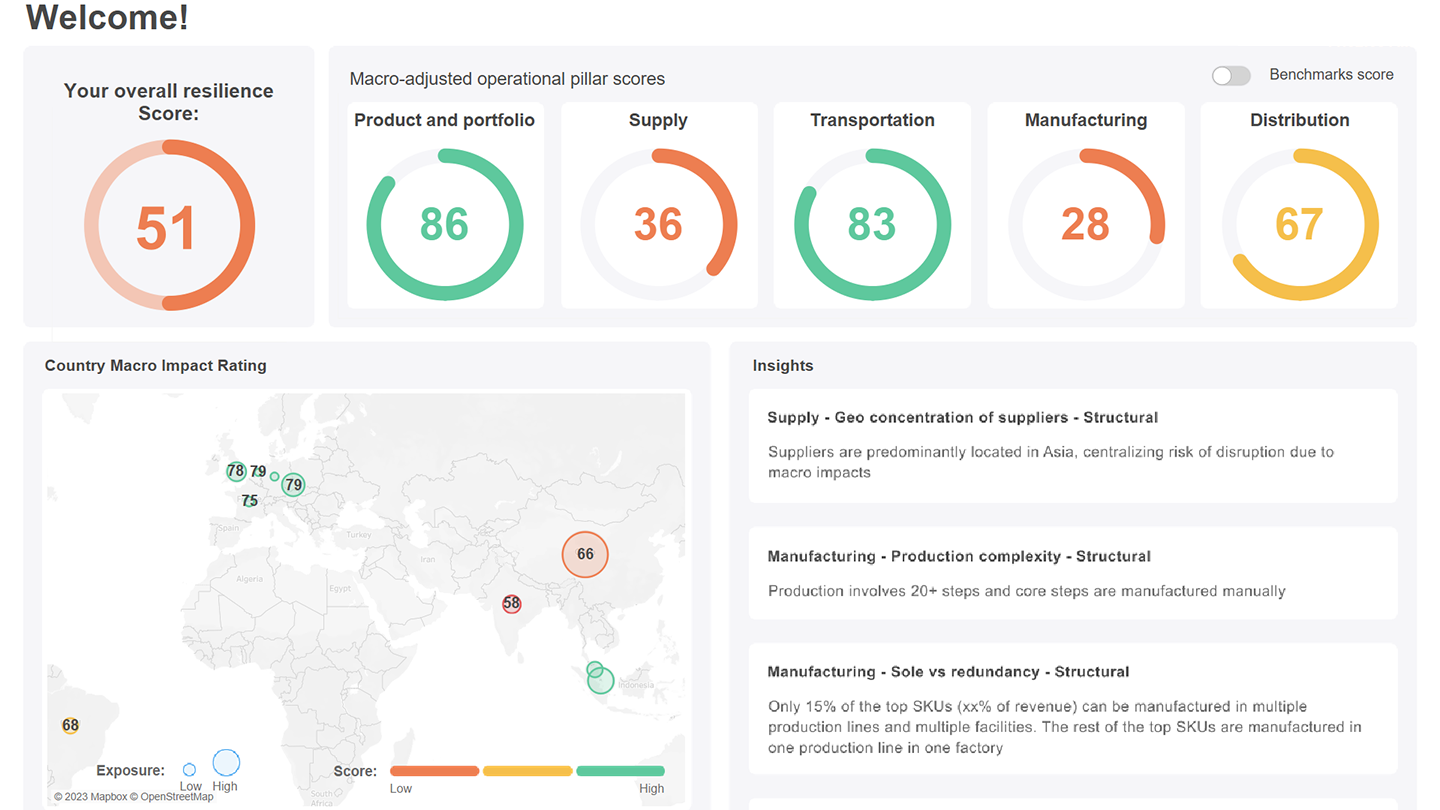

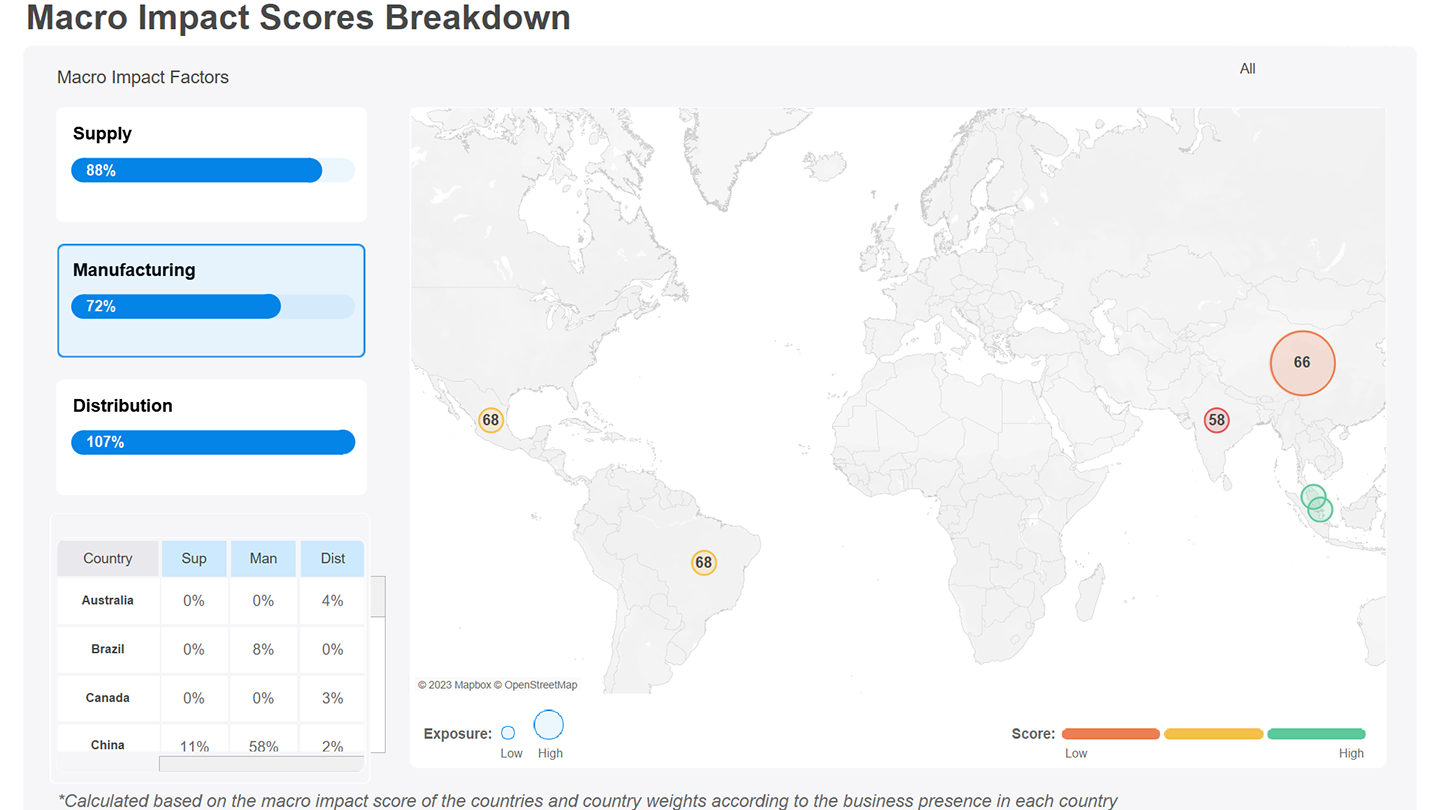

Our Supply Chain Resiliency Index is a holistic solution that identifies a broad range of potential risks, giving your organization the strength and flexibility it needs to respond immediately when the unexpected happens. Now you can spot supply chain gaps and weaknesses and correct deficiencies before they even become problems, giving you an unmistakable competitive advantage.

Using customizable weighting, we adjust the index to your highest priorities and provide an objective, outside-in identification of liabilities while also optimizing supply chain scenarios. Prioritizing resiliency is not enough; we work with you to decide what resiliency means for your business strategy and how best to mitigate risks.