Brief

The service team at a European engineering company had to act fast when an air compressor linked to medical ventilators at a large US hospital failed. Using GPS technology, customer hotline staff quickly located the nearest technician and confirmed he had the right skills and could be on site within six hours. When the problem proved difficult to diagnose, the technician donned a clip-on camera and connected via his computer to an expert at the company’s central service office in Europe, who located an inconspicuous rupture. Working together, the digitally linked team got the compressor up and running within hours. For the hospital, the rapid repair averted the need to shut down operating rooms and delay surgery at significant financial loss.

Some of the most successful industrial goods manufacturers are becoming world-class service providers—a strategy that can significantly increase revenue and, to an even larger extent, profit. Surprisingly, it’s not the particular markets served or the structure of an organization that distinguish the best service providers; it’s the right service mindset and management approach. Our experience and research show service champions free themselves from traditional thinking and focus on a few critical capabilities, including talent management, service sales effectiveness and—despite the many improvements in recent years—supply chain excellence for parts.

It’s well worth the effort. Service can be a highly profitable business in its own right for industrial goods companies, generating a better and faster return on investment than large-scale R&D programs, new production facilities or acquisitions. For many firms, investing in service is the only way to sustainably grow their profits in the current economic environment. It’s also a strategic ace. Outstanding service can elevate a company above competitors in an increasingly challenging technical environment, where differentiation based on products alone can be costly and difficult to achieve. And it enables the top performers to create growth opportunities even in a flat market. Further, service builds a two-way bridge with customers, increasing communication and intimacy—and the ability to improve new products.

Service as a path to growth and profitability

Bain’s most recent Service Benchmarking Study highlights exactly how attractive service returns are across different industrial clusters—and how to achieve them. Our research points to six key attributes that set top performers apart and measures the impact of actions encompassed under those attributes. The study, which canvassed 45 leading European manufacturers with global service operations, includes a comprehensive service-benchmarking database with more than 120 key performance indicators for service businesses.

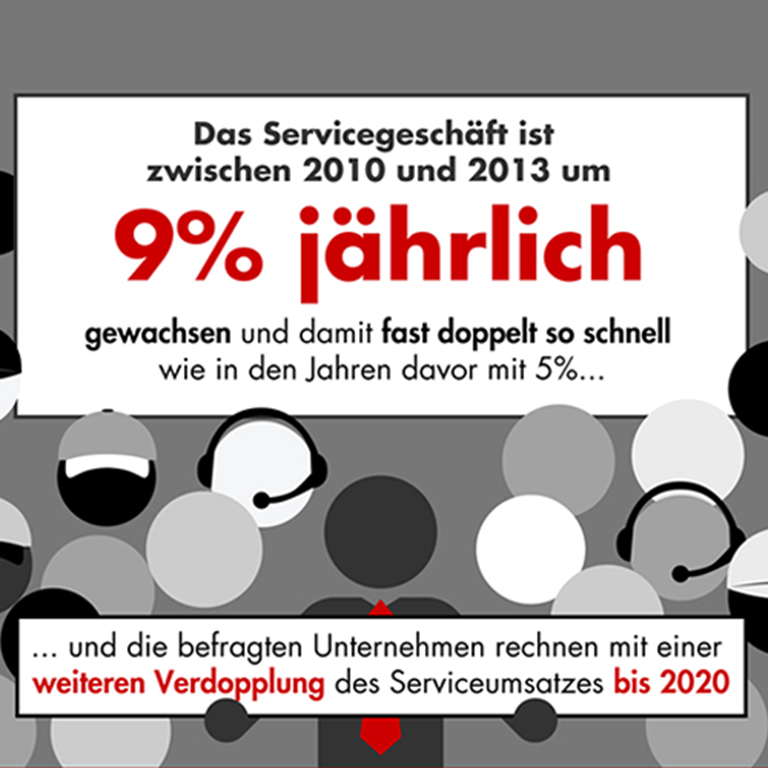

Across a broad cross section of industrial companies, service contributed 22% of total revenues and had an average gross margin of 39%—significantly higher than margins on most manufactured products, according to the study. On average, the service business of these companies grew by 9% annually between 2010 and 2013, nearly double new equipment sales (see Figure 1). That’s a sharp increase from the 5% growth rate captured in Bain’s 2012 report, Service now! Time to wake up the sleeping giant, and the companies surveyed expect the trajectory to continue. By 2020, they said, service revenue is likely to nearly double. The reason is clear: In the recent downturn, industrial companies discovered that a well-managed service business can keep growth humming even when capital expenditure is low. Indeed, the Bain study findings reinforce the value of service as a growth engine for manufacturers.

Service market characteristics vary significantly across clusters, and our research highlights the financial profile and service business profile of each cluster. Components and products manufacturers, for example, often focus their service offering on spare parts, leaving basic service execution to a network of partners. The whole cluster, including champions as well as followers, reported the lowest average share of service (12% in our database) and the highest service margins (46%), reflecting the high weight of spare parts in their business mix.

Equipment makers, by contrast, provide a full range of knowledge-based services, including maintenance, repair, upgrades, retrofits, asset management and operations outsourcing. They have a higher average share of service business (25%), but relatively lower service margins (42%) than the components-and-products cluster, as their mix of services includes more labor and expertise-based services.

Systems and plant engineering companies aim to offer the same breadth of service as equipment makers, but this group, with its close link to the installed base, focuses more on operations support and asset management. They have the same share of service (25%) as equipment makers but the lowest margins (30%) of the three clusters studied, reflecting the high engineering content of their service offering and low share of captive parts.

Champions excel along these criteria. Figure 2 shows how the performance of champions, defined as companies in the top quartile for the majority of the criteria, differs from cluster to cluster. For example, champions in the equipment cluster reach service margins of 50% and above, twice the average of the cluster.

These criteria and the variations in the performance ranges can be valuable to industrial service providers as a means of benchmarking their performance against true peers.

How to win in service

There’s no uniform model for building a world-class service business. The study found top performers in many different markets, regardless of the types of customers served or the organizational setup. And service champions, in all clusters, had higher margins than the average of all surveyed companies: Champions’ average gross margin was 46%, compared with followers’ at 37%.

The study identifies six common attributes that clearly set service champions apart from competitors (see Figure 3):

1. A clear, well-structured service offering

Key insight: Service champions redefine the customer as a strategic partner, and they articulate well-defined hierarchical service offerings with clear value propositions that increase their customers’ business performance. In return, service champions achieve strong service sales growth and deliver above-average margins in all service businesses, including labor-intensive ones such as maintenance and repair. But it’s not just about revenue growth and profits: A well-designed service business bolsters customer loyalty and can become the foundation of a long-term partnership spanning the entire product life cycle.

Many industrial companies fail to grasp how critical service is to their customers. Service champions rush to fill the void. They create a comprehensive range of offerings, structured in a clear portfolio tailored to customers’ needs. A standard package typically covers routine inspections. Modular add-ons offer preventive maintenance, reactive maintenance and repairs, and spare parts coverage, often with the option to choose from different service levels.

Service leaders tap innovative pricing models and bundle services and parts (see Figure 4). Under a more premium package, for example, technicians deployed to service a machine would take time to evaluate the adjacent machine and signal whether it requires maintenance ahead of schedule. Once customers agree to a service package, champions progressively deepen the relationship. The Bain study identified two emerging service trends: value-based pricing and connectivity services, including remote diagnostics and intervention. Value-based pricing is already a rapidly growing trend, while connectivity services will become increasingly important with the development of advanced manufacturing concepts based on digitalization. Service leaders adeptly use both to increase service sales.

- Value-based pricing as well as pricing models that share risk and performance help deepen partnerships with customers. Differentiated pricing can also reflect the value of increased uptime and productivity. Productivity-based service contracts, such as pay for uptime or pay-per-produced unit, for example, guarantee a certain level of equipment performance. More than 80% of service champions in the Bain survey employ value-based pricing models.

- The technology that supports connectivity services is enabling a new set of remote service options that can increase sales, such as emergency help to quickly get machines up and running, preventive maintenance and remote monitoring of plants. Remote monitoring involves installing diagnostic tools in customers’ equipment and tracking performance from a central control room. While the technology has been around for a while now, service champions increasingly view connectivity services as a transformative tool that allows them to stay linked with their products, develop significant new business opportunities and reduce the cost of service delivery.

While IP-connectivity and connectivity services technologies are penetrating many industries, most industrial companies are only beginning to define the business and service models that will transform data into revenue and growth. Beyond the classic “condition monitoring,” some players take a pioneering role in the changing competitive landscape. One European construction equipment company offers an energy-saving service based on connectivity services. Using a remote monitoring system to collect data from its equipment, the company analyses energy performance under different load conditions. The service constantly recommends adjustments in production processes for maximum energy efficiency—and customers pay a percentage of the actual energy saved.

2. Proactive sales approach

Key insight: Service champions use a dedicated salesforce including technical experts and generate orders through multiple channels, including online sales, and information gathered through remote monitoring of equipment. They seek business opportunities throughout the life cycle of the equipment—from new equipment sales to upgrades and replacement of aging machinery (see Figure 5).

Top performers make sure service is sold in tandem with new equipment, so as new machinery leaves the factory, it is attached to a service contract. That proactive approach not only boosts service sales, it creates a valuable record about the installed base of equipment and ensures a clear handover from new equipment sales to service. Service champions achieve an attach rate of just above 20% on average—but many aim for more than 50%. How? They make sure the service team educates the new equipment salesforce and teams up with it to improve the attach rate. Champions also create aligned incentives for the new equipment sales managers to sell service contracts.

Once the equipment is up and running, champions track its location, technical status and performance in order to create sales leads for the dedicated service sales team. With this knowledge, service sales can regularly flag maintenance milestones and possible upgrades. One global power generation company in the study launched a sales campaign based on knowledge of the installed base and sold more than 100 additional service contracts in six months in one country alone.

Service sales people need be local and in frequent contact with customer operations managers. One plant engineering company in the study uses experts working at customers’ sites to create additional sales leads by helping plan the service year with the customer and coordinating service delivery.

Total site assessments are another highly effective tool for increasing service coverage. They include a broad review of operations, from maintenance procedures and supply of spare parts to downtime. More important, they benchmark the customers’ equipment against competitors and highlight gaps. That analysis builds a business case for additional sales of both equipment and service. Many customers recognize the economic benefits of preventive maintenance and upgrades, and request the support of a full-time resident engineer.

One mining company that participated in Bain’s Service Benchmarking Study increased its service sales significantly by offering a total process assessment of client sites, including analysis of potential upgrades and modifications to improve plant efficiency and deliver cost savings. The results of the pilot so far: 25% of customers approached have signed total site assessment contracts, 50% are close to signing and the remaining 25% are in progress.

3. Active focus on delivery performance

Key insight: A strong focus on capabilities, effectiveness and efficiency delivers higher service profitability. Champions have the right technical and commercial capabilities. They make it a priority to intervene quickly—and get service right the first time.

Service champions are passionate about avoiding production downtime that can devastate a customer’s bottom line. They make it top priority to get fixes right the first time and to increase the intervals between failures. For that, they train technicians continually, provide the best possible information about the incidence before the intervention and ensure the availability of the right parts. That approach allowed one champion in our study to achieve a 96% first-time fix rate.

If repairs don’t have to be redone, everyone’s bottom line benefits, including the service provider’s. Champions’ efficient organization and sophisticated tool set help them achieve an average billable utilization rate that is 11 percentage points higher than that of followers.

Which service tools are critical for improving service efficiency? Service champions deploy multiple support structures, including custom-built service apps and advanced communication functions or handheld tools for real-time support. Advanced installed-base management tools let service providers use handheld devices to access blueprints and service schedules, and order spare parts for a particular machine. Properly equipped technicians can dispense with taking down physical information, as almost all of it can be conveyed online.

To dispatch service personnel efficiently, they use enterprise resource planning systems combined with GPS; these systems help them choose the closest and best-suited technician for each service intervention.

Even for products-and-components providers that do not have their own field force, service tools can help increase efficiency. One company in our study boosted its EBIT service margin several percentage points by setting up an integrated IT-based management system for its network of 300 indirect service partners. To ensure one reliable global service standard, the company established clear performance goals for each partner and created a dealer evaluation system to monitor performance. It also benchmarked service partners and regularly shared best practices.

4. Fast response through parts supply chain efficiency

Key insight: Service champions invest in dedicated and collaborative service supply chains and management. Supplying spare parts to customers is still the largest service business across clusters, averaging 49% of the total service business (see Figure 6). A good parts supply chain is vital for fast, accurate and efficient delivery—and a weak one seriously undercuts the entire service business.

For customers, parts supply and service is mission critical. While most companies recognize the value of a high-margin spare parts business, only some companies have a systematic way of capturing its full potential—and many even fail at the basics, including getting the right part to the customer at the right time. Top service providers go for developing the full potential of spare parts service, making efficient procurement, on-time delivery and shortened-response times priorities. They use dedicated supply chains and a global coordinated, tiered warehouse structure to increase availability, speed and accuracy. Our study showed service champions deliver on time in 89% of cases, compared with 80% for followers.

The best-performing companies also typically create stand-alone service businesses with full control over spare parts delivery. One European equipment maker set up four global logistics centers around the world—in Germany, the US, Japan and Hong Kong. Customers can order around the clock seven days a week, with 95% of merchandise available directly upon receipt of order and delivery to almost anywhere in the world within 24 hours.

Going one step further, a European machinery company established a service fast lane in its manufacturing operations to speed the repair of key components, managing the fast lane as a separate business. The company offers four repair options ranging from standard, with a repair lead time of six weeks, to premium, with a one-day repair turnaround. The one-day offer, which carries a price premium, includes joint monitoring of systems with continuous maintenance schemes and stocking of key components at the supplier’s site. And to ensure the service fast lane doesn’t sit idle, its service managers negotiate spare parts framework contracts with customers, including annual threshold volumes.

In addition to improving speed and accuracy of parts delivery, a dedicated service supply chain increases customer trust and satisfaction. And a relationship based on reliability rather than price creates further reasons for the customer to use original parts over third-party parts.

5. Managing talent and people for service excellence

Key insight: Service is a people business. While industrial suppliers historically excel in engineering and manufacturing, their service business poses a wholly new challenge in terms of people and talent management. Champions use specialized human resources to hire and develop service experts who are both technically experienced and commercially savvy—a rare combination. And they create attractive career paths to retain their multi-talented service team in the face of high market demand and high turnover. According to the Bain study, talent management is an increasingly strong differentiator in service, particularly in emerging markets.

Effective people management also increases workforce loyalty, motivation and identification with the company. Lower employee turnover, in turn, improves efficiency and generates significant cost savings. Our study reveals a huge gap between the worst performers, which reported attrition rates of 10% to 15%, and the best-in-class companies with rates as low as 1% to 2% (see Figure 7).

Service champions know that the best service employees can have their pick of top jobs—and the better the service team, the more vulnerable it is to high fluctuation. Rival service providers and even their own customers compete for the very same people. In some cases, entire service teams have quit simultaneously and set up competing service boutiques successfully. To avoid high turnover, service champions make talent management a top priority and design initiatives to recruit, train and retain their service managers and technicians, adapting these measures to local markets.

Many industrial companies neglect the career paths of their service employees. Champions give service employees the attention they deserve, using specialized human resources and processes for hiring, training and managing the attrition of service staff. For new recruits they accelerate the learning curve, making sure young technicians quickly become as effective as experienced colleagues. One leading turbine supplier in the study defined service as the preferred “entry gate” for new employees. It designed a two-year program pairing university graduates with experienced service technicians and combining advanced formal training with first-hand service experience around the globe—a key attraction for young recruits. Employees who complete the program gain a comprehensive understanding of customer needs and priorities, as well as thorough knowledge of the company’s products, culture and global organization.

To retain top talent, service champions design interesting and rewarding career paths and offer a variety of financial and nonfinancial incentives. One European automation systems company, for example, now treats service employees on a par with new equipment engineers, offering them multiple career opportunities in service, attractive remuneration, deferred bonuses, above-standard health benefits and a clutch of give-aways—from car safety seats for kids to sharing schooling costs. It also set up a central unit to understand service employee departures and draw lessons learned. Finally, it created an early warning system to track global attrition. The results were striking: The company’s worldwide attrition rate for service technicians dropped below 2%, less than half the 5% average rate for the companies surveyed.

To achieve those gains, the company developed clear processes for personnel planning, hiring and talent management, including recruiting targets by country, using dedicated and specialized service human resources staff to plan and implement new processes. It also established flexible, long-term career plans for service technicians linked to job grades, training programs and competence development—including positions that do not require constant travel.

Lower attrition rates reduce the costs of operating a service business. More experienced people are better at managing the disparate service issues that arise across a company’s installed base. A talented service team improves efficiency, lowers costs and increases revenue by driving demand for service offerings. Many differences in service penetration that can be observed across countries for a certain company have more to do with the quality of local teams than any other factor.

Recognizing the importance of service, a leading robotics manufacturer made it an integral step in the career trajectory of its top management. To progress in the company, managers must not only head a unit in emerging markets, but also successfully manage and grow a service profit center.

Globalization has made talent management a key challenge for most companies. Service champions recognize that building and retaining service talent is not only a human resources problem to solve tactically. It is a strategic ace that catapults them ahead of the competition.

6. Transparency in performance management

Key insight: While most companies monitor the financial performance of the service business, service champions track and steer local units closely and offer comprehensive support to foster top performance. They use a more comprehensive set of key performance indicators that are specific for service performance and work with data to manage the business profitably (see Figure 8). When performance lags, red flags go up, just as in manufacturing.

A transparent system to measure performance, coupled with systematic links to action, helps service champions deliver an 83% overall utilization rate, compared with 72% for followers. The spread is even larger when comparing the best performers, which have a utilization rate of over 90%, with the worst, which are below 50%. Clearly, the profitability per full-time service employee varies broadly in such cases.

One HVAC company created a strong central service department to support local units, freeing them from overhead tasks so they could fully focus on local service. The company also used key performance indicators and peer audits to achieve superior performance across its far-flung service operations. During audits, for example, the auditor and auditee shared best practices and improved service quality together, empowering the branches.

In this short video, Bain Partner Oliver Straehle explains six elements that service champions get right.

The road ahead

Service is more resilient and less cyclical than most of the underlying industrial products and equipment business. And with its above-average profitability and growth, service is a highly attractive stand-alone business. More important, it is a key weapon in the intensifying battle for technical differentiation and commercial value proposition, which every industrial company is fighting.

Today, service champions achieve significantly better financial results than followers—both overall and in service. They outperform by pulling six operational levers, from developing a service offering as detailed and accessible as a new product catalog to precisely managing the daily performance of their service technicians.

For service champions, the road ahead is promising. Their strengths will allow them to grow faster than the competition and develop stronger partnerships with customers. Because they create more value for their customers, champions are more difficult to challenge. From this advantageous position, they have strong foundations to continue to out-innovate, out-earn and outperform their peers. Champions see their service strategy as an increasingly important part of their overall strategy. Top management’s recognition of the strategic role of service is helping spur radical innovations, from new commercial models to complete IP connectivity.

For others, the time to act is now. Companies that don’t have a service strategy should define one—including where to play and how to win. These companies can benefit from the learning curve of service champions. For them, the Bain 2014 Service Benchmarking Study offers a tool to quickly assess their service performance along 120 key performance indicators, as well as a unique collection of best practices to develop their service strategy.

Looking further into the future, digitalization of the entire value chain will affect service significantly. Be it 3-D printing of spare parts, e-channels or connectivity services based on Big Data and advanced analytics, to name only a few, many new service opportunities are arising, together with new challenges. The leaders will find ways to stay close to these developments and make the most of them.

Six service myths

The Bain Benchmarking Study reveals six common truths and myths about industrial service businesses:

1. Service sales only grow if new equipment sales grow

No. Service businesses grow independently of new equipment sales. Most companies increase service revenues by selling more to their own installed base, but also to new customers by embracing a more proactive approach and developing innovative new service models that offer value and share risk.

2. Fast-growing service businesses eventually reach saturation

No. Even service champions with a high share of their customers’ wallet keep growing through new customers and third-party businesses—the market does not limit service sales. The top five champions by service share (46% on average) grew by an average of 10% from 2010 through 2013.

3. Margins on maintenance and repairs dilute the margin of the overall service business

Generally true. But service champions break the rule. They actually achieve the same margins solely on their maintenance and repair operations (37% on average) as the margins followers make on their total service business. The right definition of service offerings, smart customer targeting and excellent delivery make labor-based services an attractive business while protecting the spare parts business.

4. The fastest-growing service businesses are those run as independent organizations

No. Many high-growth service businesses are not independent business units. Service businesses run as dedicated businesses grow as fast as others—9% per annum, on average. Initially, it is often better to create a separate unit to foster ownership and specialization, dedicated resources and a service-specific supply chain. But once the unit is properly set up, service can be brought closer to new business operations to leverage cross-selling and other benefits.

5. Selling through indirect channels makes it difficult to maintain high service margins

Yes, but some companies outperform through indirect channels. They establish a global service strategy with well-defined goals, audit channel partners’ performance, and use incentives and penalties. Even components makers can run a thriving service business by stimulating demand for service and carefully managing the relationship with channel partners.

6. It is very difficult to grow a service business in Asian markets

It is difficult, but service champions do it better than their rivals. In Asia, champions achieve the same service penetration they achieve in Europe or the Americas, albeit mostly on a smaller installed base.

Methodology

The Bain Service Benchmarking Study is based on an extensive survey and interviews conducted from June 2014 to November 2014 with a broad and representative panel of 45 global industrial goods companies headquartered in Europe with global service operations. We aggregated and published the findings in this report and discussed key insights and trends with companies individually. The study compares the main service performance indicators of participating companies across three industrial clusters: equipment manufacturing, components and products, and systems and plant engineering. It also analyzes the key attributes of service champions and the actions contributing to their strong performance.

Oliver Straehle and Pascal Roth are partners with Bain & Company based in Zurich. Christoph Herr is a Bain principal in Düsseldorf.

The authors would like to thank those who participated in the Bain Service Benchmarking Study, as well as Adrien Bron, Martin Nilvall and Maximilian Köpke for their contributions. They are also grateful to Bain Partners François Montaville, Magnus Burling and Andrea Isabella for their support in leading the survey project. Finally, they would like to thank Pierre Deraëd and Katharina Weindl for marketing support.